Exactly How Light Weight Aluminum Casting Adds To Efficient Production Solutions

Aluminum spreading plays a crucial duty in modern-day manufacturing. Its light-weight nature and deterioration resistance make it a recommended choice for various industries. Methods such as die casting and sand casting permit the creation of elaborate get rid of minimal waste. The assimilation of automation additional enhances production performance. The ramifications of these developments extend past plain performance - Precision aluminum casting. Recognizing the more comprehensive influence exposes substantial insights into the future of production

The Advantages of Aluminum in Manufacturing

Various metals are utilized in production, light weight aluminum stands out due to its special residential or commercial properties that enhance manufacturing efficiency and item efficiency. Its lightweight nature notably reduces transportation prices and power requirements in numerous applications. Light weight aluminum's superb corrosion resistance guarantees durability and resilience, minimizing the demand for frequent replacements and maintenance. This metal can be conveniently built and shaped, enabling for flexible style choices that satisfy details sector needs. Additionally, aluminum exhibits premium thermal and electrical conductivity, making it an excellent option for applications requiring efficient heat dissipation and electrical monitoring. The recyclability of aluminum likewise plays an important function in lasting production methods, as it can be recycled without losing its intrinsic residential properties. Generally, the benefits of light weight aluminum in manufacturing bring about cost financial savings, boosted item longevity, and a reduced ecological impact, making it a favored material in many markets.

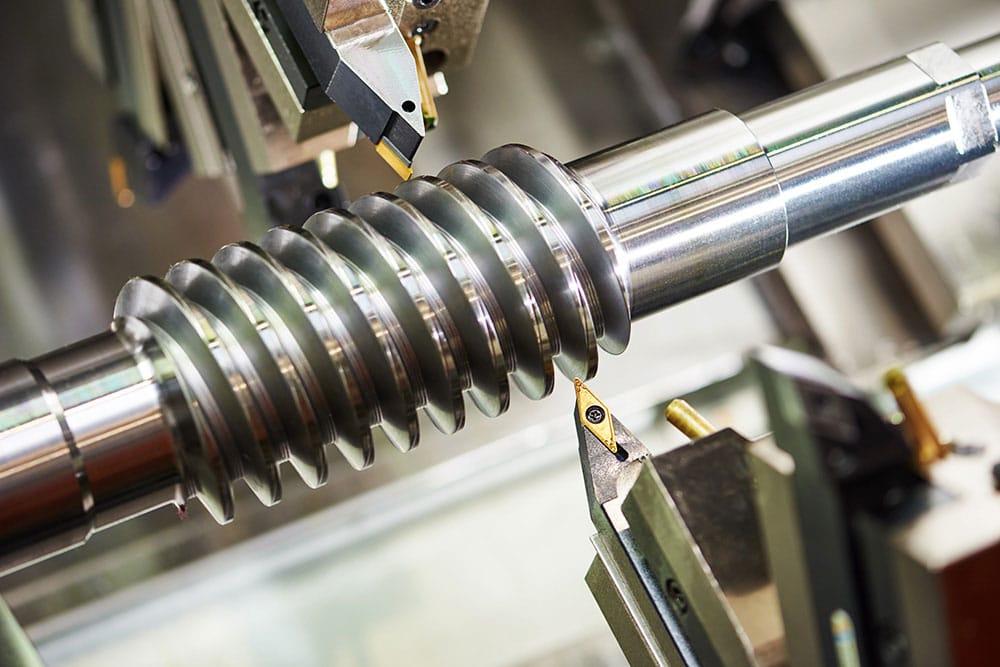

Key Light Weight Aluminum Casting Techniques

Light weight aluminum casting techniques are important for producing top notch components in numerous producing procedures. The main methods consist of sand casting, pass away casting, and financial investment casting. Sand casting entails creating a mold and mildew from sand, which enables large elements and complex shapes. This method is frequently favored for its cost-effectiveness and versatility. Die spreading, on the other hand, utilizes high-pressure to infuse liquified light weight aluminum right into steel mold and mildews, resulting in accurate, consistent components ideal for high-volume production. Financial investment casting provides remarkable surface area finish and elaborate information by making use of a wax pattern that is disappeared to form the mold. Each of these methods has details applications and benefits, allowing manufacturers to select one of the most suitable approach based on factors like production material, quantity, and intricacy specs. By recognizing these key strategies, manufacturers can improve their manufacturing effectiveness and assure the honesty of their light weight aluminum parts.

Effect On Automotive Industry

As the vehicle market significantly focuses on light-weight materials to boost gas effectiveness and performance, aluminum spreading has actually arised as a crucial solution. This production procedure permits car manufacturers to create intricate parts with reduced weight without compromising structural integrity. By utilizing aluminum casting, manufacturers can produce parts such as engine blocks, transmission housings, and suspension elements that are not just lighter however likewise display excellent thermal conductivity and rust resistance.

The versatility of aluminum casting strategies allows the production of complex designs, promoting advancement in vehicle appearances and performance. As lorries come to be more highly advanced, the capability to incorporate functions like advanced safety and security systems and electric drivetrains comes to be important.

Aerospace Applications of Light Weight Aluminum Spreading

Light weight aluminum casting plays a critical duty in aerospace applications by allowing the production of lightweight structural parts that enhance gas performance. Additionally, the precision of light weight aluminum casting permits the development of elaborate engine components, which are vital for peak efficiency and reliability. This mix of lightweight materials and precise engineering placements aluminum casting as an essential modern technology in the aerospace market.

Lightweight Structural Components

In the pursuit for enhanced performance and performance in aerospace applications, lightweight architectural elements have become increasingly vital. Light weight aluminum spreading plays an essential role in this undertaking, offering producers with the capacity to create parts that are both light-weight and solid. The reduced thickness of aluminum permits for substantial weight decreases without endangering architectural integrity, which is important for airplane efficiency and gas efficiency. On top of that, aluminum castings can be engineered to satisfy details design requirements, making it possible for the creation of complex geometries that standard manufacturing techniques might battle to accomplish. This convenience not just streamlines production processes yet additionally contributes to general price financial savings. As the aerospace sector remains to highlight sustainability, the demand for lightweight light weight aluminum elements is expected to rise, better advancing technology in production.

Precision Engine Parts

Suppliers progressively count on aluminum casting to produce precision engine components for aerospace applications, driven by the material's unique properties. Aluminum's lightweight nature considerably reduces general airplane weight, improving fuel performance and efficiency. Its outstanding deterioration resistance warranties durability in rough atmospheres, making it perfect for important engine components. Furthermore, aluminum spreading allows for complex layouts and limited tolerances, crucial for optimizing engine performance and dependability. The spreading process also supports automation, allowing manufacturers to fulfill high need while maintaining top quality criteria. As aerospace modern technology proceeds to breakthrough, the duty of aluminum casting in creating precision engine parts will certainly be pivotal in accomplishing higher efficiency and advancement in aircraft style and performance.

Sustainability and Environmental Advantages

The growing focus on sustainability in manufacturing has actually placed light weight aluminum casting as a leading option for eco conscious production. This procedure utilizes recycled light weight aluminum, which substantially lowers energy intake compared to main light weight aluminum production. By leveraging scrap steel, makers can reduce their carbon impact and lessen waste, aligning with global sustainability objectives.

Furthermore, light weight aluminum casting produces less damaging discharges, contributing to a cleaner atmosphere. The lightweight nature of light weight aluminum additionally enhances gas efficiency in transportation applications, additionally promoting eco-friendly methods.

Moreover, the sturdiness and corrosion resistance of light weight aluminum result in longer item lifespans, decreasing the demand for frequent replacements and preserving sources. As markets significantly prioritize sustainable selections, aluminum spreading attracts attention as a cutting-edge approach that not just meets production needs however likewise sustains ecological stewardship. This dedication to sustainability settings light weight aluminum spreading as a critical player in the change towards a greener production landscape.

Price Efficiency in Manufacturing

Cost performance is a significant advantage of light weight aluminum spreading, matching its sustainability benefits - Precision aluminum casting. The procedure of light weight aluminum spreading allows for the manufacturing of complex forms with minimal waste, which is specifically vital in an affordable production setting. Making use of aluminum decreases energy costs, as it has a reduced melting point contrasted to other metals, bring about reduced energy intake throughout production

Additionally, light weight aluminum's light-weight residential or commercial properties contribute to decrease delivery and managing prices, better boosting general cost efficiency. The resilience and corrosion resistance of light weight aluminum actors items likewise suggest that they require less maintenance and substitute in time, leading to long-term savings for producers.

Additionally, innovations in casting innovations, such as boosted mold layouts and automation, have structured production processes, minimizing labor prices and raising outcome efficiency. On the whole, cost effectiveness in aluminum spreading plays an essential function in maximizing production operations and supporting affordable pricing techniques.

Future Trends in Aluminum Spreading

The future of aluminum spreading is progressively shaped by innovations in automation and sustainable product advancements. Automation innovations are anticipated to enhance efficiency and accuracy in the casting process, while sustainable methods aim to reduce ecological influence. With each other, these patterns promise to redefine manufacturing standards and techniques within the light weight aluminum casting market.

Automation in Aluminum Spreading

Embracing automation is transforming aluminum spreading procedures, leading the way for improved performance and accuracy. Automated systems improve production by minimizing human treatment, reducing errors, and enhancing throughput. Technologies such as robot arms and computer mathematical control (CNC) devices permit consistent and precise shaping of aluminum elements. Furthermore, clever sensors keep an eye on numerous criteria in real time, making certain perfect problems throughout the spreading process. This assimilation of automation not just reduces preparations but additionally enhances item high quality by maintaining tighter resistances. As makers significantly take on these advanced innovations, the aluminum spreading industry is readied to experience considerable renovations in functional effectiveness, cost-effectiveness, and competition in the international market.

Sustainable Product Innovations

Regularly Asked Questions

What Kinds Of Light Weight Aluminum Alloys Are Generally Used in Spreading?

Generally utilized light weight aluminum alloys in casting include 356, 380, and 413. These alloys are preferred for their outstanding fluidity, toughness, and rust resistance, making them suitable for a range of industrial applications.

Just How Does Light Weight Aluminum Spreading Compare to Various Other Steel Spreading Methods?

Light weight aluminum casting usually offers lower weight, remarkable corrosion resistance, and far better thermal conductivity compared to other steel casting methods. Additionally, it enables intricate designs and faster manufacturing cycles, improving total manufacturing performance and performance.

What Industries Advantage The Majority Of From Light Weight Aluminum Spreading?

The vehicle, aerospace, and electronic devices industries benefit most from aluminum casting. These markets use its lightweight, corrosion-resistant homes to enhance performance, minimize fuel consumption, and enhance total product efficiency, making aluminum spreading significantly important.

Exist Certain Layout Limitations With Aluminum Spreading?

Yes, aluminum casting has style restrictions, consisting of constraints on wall density, complicated geometry difficulties, and potential concerns with attaining tight resistances (Aluminum Casting Company). These variables can affect the total strength and functionality of the end product

How Is Quality Control Maintained in Light Weight Aluminum Spreading Processes?

Quality control in aluminum spreading processes is maintained with extensive inspections, adherence to standard procedures, and using innovative technologies. Regular monitoring guarantees dimensional accuracy, surface integrity, and product consistency throughout manufacturing, advertising general reliability.

As the automotive website market significantly focuses on light-weight products to enhance fuel performance and efficiency, light weight aluminum spreading has actually emerged as a crucial service. Light weight aluminum casting plays a crucial duty in aerospace applications by allowing the production of light-weight structural elements that boost gas performance. Price performance is a significant advantage of aluminum spreading, complementing its sustainability advantages. Embracing automation is changing light weight aluminum spreading processes, paving the means for improved efficiency and accuracy. Recycled light weight aluminum usage has actually gained grip, significantly decreasing power consumption contrasted to primary aluminum production.